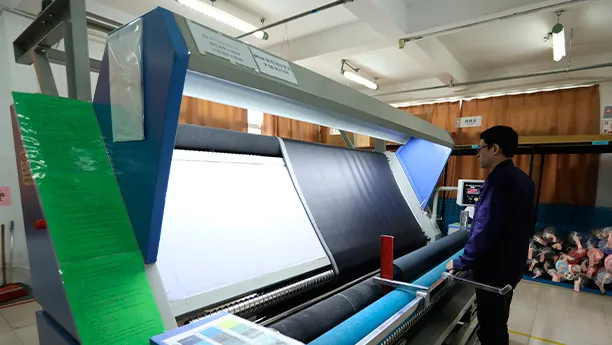

We put quality management throughout the whole process of hat production: from fabrics to semi-finished products, finished products packaging, etc., to ensure the quality of the final products. Currently, there are 30 quality inspectors and 10 inspection machines.

Inspection items: appearance, weight, density, feel, pattern, color, width, length, weft skew, and weft arc of the fabric.

We use a four-point inspection method, and each yard of defects will be rated as four points for severe deficiencies.

Example: All holes will be rated four points regardless of their diameter.

Masters cut out the panels in correct shape and size, according to the tech pack. It's the basic step before sewing the perfect hats.

Inspecting an in-line hat is to check whether the process meets the requirements of tech pack in production to discover and solve the possible quality problems in advance.

Handwriting clear or not;

The direction and location of the label qualified or not;

The content of the stitches qualified or not;

Craftmanship of the stitches qualifed or not.

Material and color of seam tape qualified or not;

Material and color of sweatband qualified or not;

Measuring head circumference size qualified or not;

Inside crown wrinkle or not;

Line blister or not.

Fabric Color qualified or not, with or without chromatic aberration;

Color and craftsmanship of the sweatband hat stitching thread, embroidery thread color qualified or not;

The peak of the cap, round or not, symmetrical, blistering, tooth printing;

Measuring head circumference size qualified or not;

The number and spacing of the hatchet derivative line qualified or not.

It is used to inspect if broken needles, broken screws or staples left on the hat during hats production, so as to eliminate the pontential risk of human injury.

We help you customize and manufacture premium hats that are worthy of your brand on time, and on budget.